Energy Efficient

Powerfoil efficiency of 12% is equivalent to the output of 18% efficiency glass solar panels. Energy efficiency is measured at Standard Test Conditions (STC) which does not reflect the actual output of the module.

More use of available area

Flexible, lightweight Powerfoil can cover 20 – 40% more surface area of rooftops than heavy, rigid glass panels. For a typical standard glass-based panels reach a maximum coverage of 60%. With the HyET Solar modules a roof coverage of up to 90% is possible. Powerfoil produces more energy at a lower LCOE for all typical roof shapes.

More power output in real operating conditions

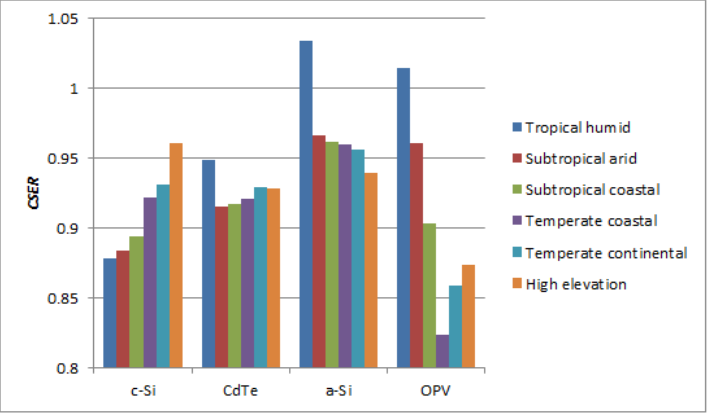

Efficiency of PV Solar products are measured at Standard Test Conditions (STC) which are 25 ºC module temperature and 1000 W/m² irradiation. However, in real operating conditions modules can easily reach 60+ °C which strongly reduces the efficiency of traditional glass-based PV systems. In most climates clouds or haze will temper the irradiation and cause more diffuse light conditions. The difference between STC and real operating conditions is expressed in the Climate Specific Energy Rating (CSER).

Powerfoil is based on amorphous silicon (a-Si:H) technology which performs better at high temperature and diffuse light conditions, resulting in 15% higher system output compared to a crystalline silicon based (c-Si) glass panel system with the same installed power.

Superior temperature coefficient

Research conducted by NREL shows a significantly better temperature coefficient of Powerfoil compared to c-Si. Overall, at the higher operating temperatures typical in high desert, the a-Si Powerfoil shows a lower loss in energy yield as compared to conventional C-Si PV technology. Experimental methods Determination of the temperature coefficient requires investigation of the reduction of conversion as a result of an increased temperature. Therefore, a set-up was used in which flash testing is performed on modules that are heated from room temperature to 75°C. The flash tester used is the SPI-SUN Simulator 5600SLP, of which the flash testing was set to the STC irradiation of 1000Wm−2 . A structure was placed on top of the flash tester through which hot air was circulated to increase the temperature of the modules. The temperature measurements were performed using 16 Omega SA-1 thermocouples on the back of the modules. A high-end quality crystalline silicon reference cell was added to investigate the difference in temperature coefficients. Results The result of the temperature coefficient tests for both amorphous silicon and crystalline silicon are provided in Figure 1. The results were extrapolated from 75°C to 100°C as the experiment could go to a maximum temperature of 75°C. What can be observed is that amorphous silicon has a significant advantage over crystalline silicon with regards to the temperature coefficient. The amorphous silicon temperature coefficient has three different slopes: −0.00049°C−1 between 25°C to 30°C, −0.00148°C−1 between 30°C to 50°C and −0.00227°C−1 between 50°C to 75°C. In contrast, crystalline silicon has a consistent temperature coefficient of −0.00274°C−1 , which is higher than the steepest slope for amorphous silicon. Important to point out is that the NREL scientist Dr. Paul Ndione that led the measurements insisted that the crystalline silicon sample was in the top and most C-Si PV technologies on the market. Considering a temperature of 85°C, Powerfoil has at least a 6% lower power loss than crystalline silicon technology.

.png)