Thin Film composition

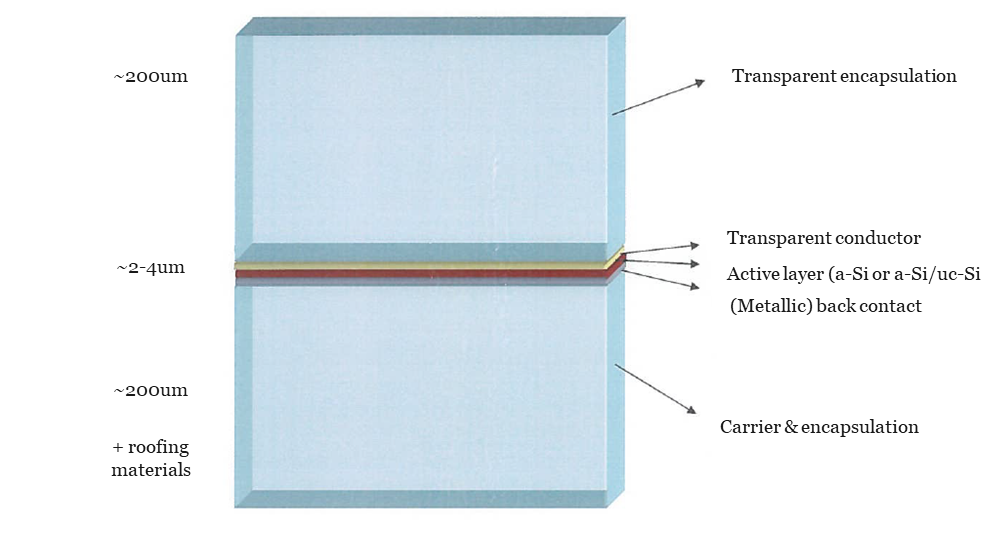

The transparent top-encapsulant is made of a high translucent fluorinated-polymer that is water repellant and non-sticking, hence easy-to-clean

The unique Transparent Conductive Oxide (TCO) is trapping the transmitted sunlight in the active silicon layer to endow maximum conversion of photons to electrons.

The semiconductor layer (a-Si / uc-Si) is causing part of the electromagnetic spectrum of the solar energy to be converted in to an electrical current.

The metallic back contact and the TCO layer conduct the current to the aluminum busbars on each side of the foil

The polymer carrier and back encapsulant provide support to the foil and create an interface to the adhesive layer for attachment to various surface substrates

Sustainable

Compared to other Thin Film solar panels Powerfoil consist of non-toxic, abundantly available raw materials that are inexpensive. Hence already at low production volumes the costs will be lower than the mass-produced glass panels. The abundance of raw materials such as Silane, SnO2, ZnO and polymers make Powerfoil a very scalable product with a minimum ecological footprint.

No scarcity is to be expected for any of these materials in the medium-long term. The use of these materials in the HyET Solar modules is so small compared to world production volumes, that large production growth will not lead to a sudden rise in the total global demand. Powerfoil raw materials are freely traded in every country in the world.

Thin Film composition

- The transparent top-encapsulant is made of a high translucent fluorinated-polymer that is water repellant and non-sticking, hence easy-to-clean

- The unique Transparent Conductive Oxide (TCO) is trapping the transmitted sunlight in the active silicon layer to endow maximum conversion of photons to electrons.

- The semiconductor layer (a-Si / uc-Si) is causing part the electromagnetic spectrum of the solar energy to be converted in to an electrical current.

- The metallic back contact and the TCO layer conduct the current to the aluminum busbars on each side of the foil

- The polymer carrier and back encapsulant provide support to the foil and create an interface to the adhesive layer for attachment to various surface substrates

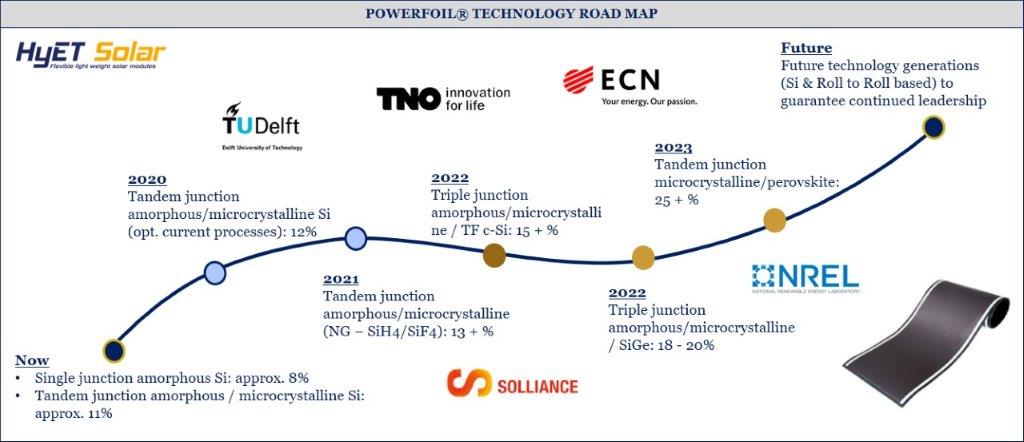

Conversion efficiency

Powerfoil can be produced with two active layers (tandem junction) achieving a conversion efficiency of 12% at STC, which in real operating conditions matches conventional c-Si based glass panels, however at a fraction of the costs. A rigorous roadmap is aimed at the production of triple junction Powerfoil product that will have an efficiency of 26%. HyET believes performance is only partly determined by conversion efficiency. Equally important is the total system output which for a-Si PV cells is higher because it perform better in diffuse light conditions and with partially shading when compared to conventional glass panels.

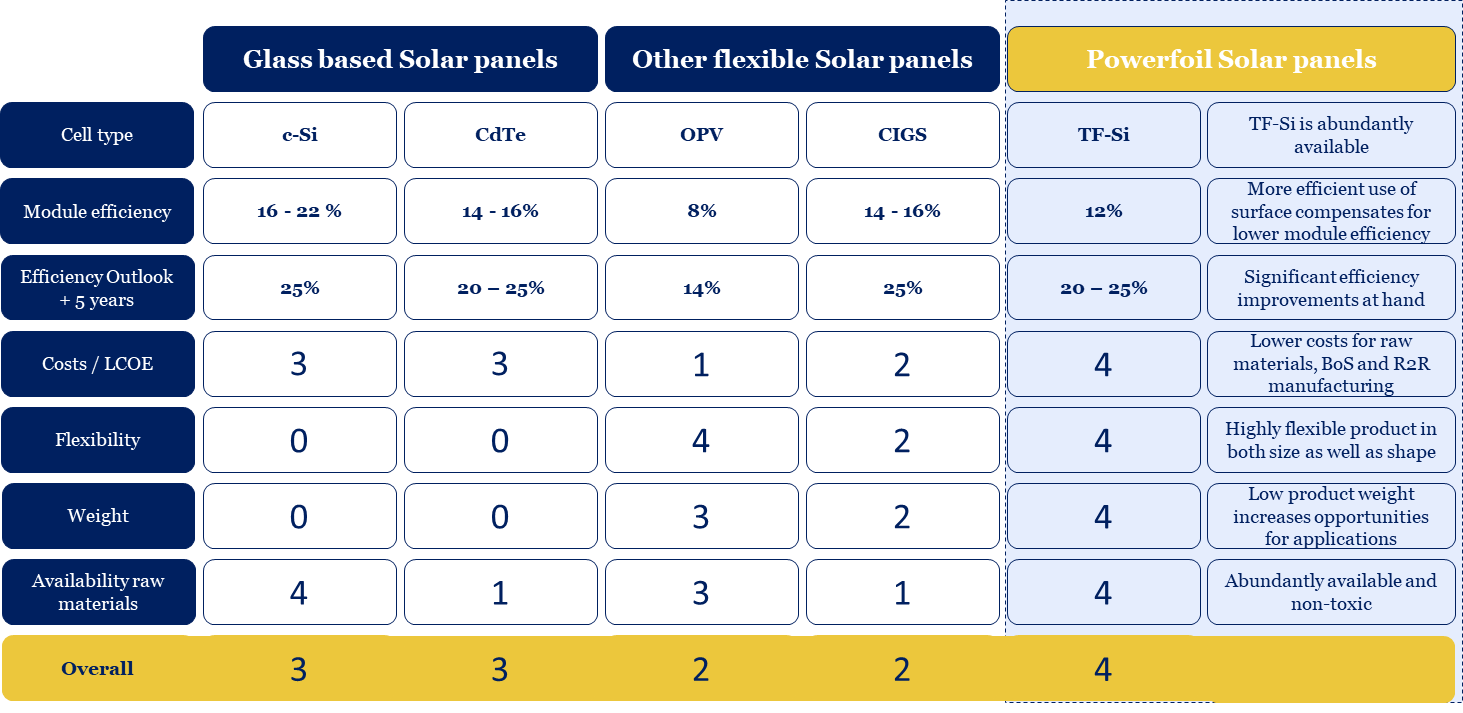

Competitiveness

When compared to the most common PV technologies, Powerfoil technology outperforms on the main performance indicators delivering the lowest LCOE for most applications.

Sustainable and inexpensive

Compared to other Thin Film solar panels Powerfoil consist of non-toxic, abundantly available raw materials that are inexpensive. Hence already at low production volumes the costs will be lower than the mass-produced glass panels. The abundancy of raw materials such as Silane, SnO2, ZnO and polymers make Powerfoil a very scalable product with a minimum ecological footprint.

No scarcity is to be expected for any of these materials in the medium-long term. The use of these materials in the HyET Solar modules is so small compared to world production volumes, that large production growth will not lead to a sudden rise in the total global demand. Powerfoil raw materials are freely traded in every country in the world.